Clio Single-Use-Pump's (SUP) all consist of

The Clio Air-Operated-Diaphragm-Positive-Displacement (AODPD) OneWay direction LASER guided Single-Use-Pump (SUP) cell’s consist of a housing integrating a valve body, a dome, the diaphragm, LASER support and the fluid conveying hoses – all supplied pre-sterilized in dual film bags.

|

Stand-alone product, model names |

CM80 |

CM100 |

CM140 |

CM200 |

CM300 |

|

Layout, number of diaphragms |

single |

single |

single |

single |

single |

|

Diaphragm diameter, mm |

80 |

100 |

140 |

200 |

300 |

|

Stroke Volume, SV, mL / 100 % stroke |

50 |

200 |

500 |

1,200 |

3,000 |

|

Cardiac Output, CO range, max mL / min |

450 |

1,500 |

2,500 |

9,500 |

18,000 |

|

Beats-per-Minute, BpM, depending on stroke and valve technology used |

0 - ~18 |

0 - ~15 |

0 - ~10 |

0 - ~8 |

0 - ~6 |

|

Typical hose connection, ID/OD mm |

4/8 |

8/12 |

12/18 |

18/24 |

|

|

SUP cell weight, grams |

100 |

200 |

300 |

600 |

2000 |

|

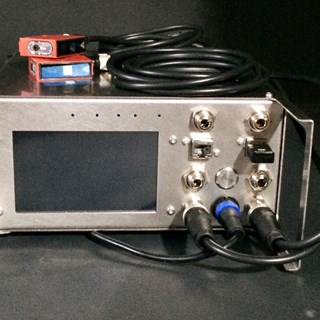

Drive Unit |

Clotho |

Clotho |

Lachesis |

Lachesis |

Atropos |

The basics in operation is copied from the human heart functionality:

- Cardiac Output (CO) = total pumped volume, SUP capacity, ml/min (CO = BpM x SV)

- Beats-per-Minute (BpM) = ranging 0 - 18 BpM, SUP diameter/stroke/volume depending

- Stroke Volume (SV) = programmable from 1 - 100% of SUP cell specification

Physical features

- No expensive housing materials for traditional steam cleaning requirements

- No mechanical axle seals

- No mechanical rotating parts such as electrical motor, coupling or gears

- No moving ball valves, only passive cross-slit silicone valves

- All simple single-use plastic parts – contamination eliminated

- Low weight and compact design give OEM manufactures new freedom to design equipment

- Measures accurately pumped volume, a true Positive Displacement pump – no in-line flow-sensor is needed

- All pumps offer infinite turn-down, turn-up scale of 1:5,000

Operating features

- Volumetric operation precision better than 1% - without any extra flow sensor

- Volume per stroke depending on pump size - no minimum volume exist

- Zero spallation / shedding of membrane materials – low shear forces

- Self-priming from 2 meter suction height

- Standard fluid pressure 1 bar - higher pressure like 3-5 Bar require customized body

- No need for calibration - build in artificial intelligence in Drive Unit

- Pump any fluid - any mixture of liquid and gases

- Dry running for extended periods

- Self-emptying, drain on inlet and purge on outlet as the pump will convey gas as well

- Single-use, disposable wetted parts eliminate cleaning issues – just un-pack and exchange without any tools needed

- Very gently operation with no rotating or rubbing parts - no shear introduced between used polymeric materials parts creating nano size polluting particles

- Working pressure as much as 5 Bar on special models makes the SUP suitable for connection with filtration devices

- Two pumps able to operate fully controlled and in parallel when connected to Clotho-2

Programming features

- Select the continuous volume you want to pump – (well, according to pump size)

- Select the total volume you want to pump

- Select the time you want the pump to operate

- Real-time information about pumping, pumped volume and velocity

Maintenance features

- No tools needed replacing the SUP cell - takes only one minute !

- No lubrication needed

- No need to strip down pump for cleaning

- Longevity - tested to last 0.5 million cycles at 75% CO

Installation features

- Single-Use-Pump cell may easily be part of an all sterile process package

- No tooling needed for Single-Use-Pump cell replacement - one minute operation

Data collection features of the drive Unit

- On-line operation pressure measured by build-in pressure sensor

- On-line Mass-Flow-Control / metering, the pump measures the volume pumped with better than 1% accuracy - without external flow sensors!

- Data acquisition, data logging

Communication features of the drive unit

- OPC-UA allow connection various software, such as DeltaV, Lucullus, DasWare

- Single-Use-Pump cell's need connection to Drive Unit (requires pressurized air, vacuum and 24 VDC electrical power)

- TCP/IP bus connection or Wi-Fi connection

- All Drive Units operate both as stand-alone or combined with other devices

- Clotho and Lachesis and Atropos software are more or less identical and easy up-gradable

- Clotho, Lachesis, Atropos units facilitate a webhost, which allow the user to access the Drive Units via Wi-Fi as well as via IP/TCP from many devices via Ethernet, USB connection (for data export), OPC-UA communication

- Access Clotho, Lachesis, Atropos via build-in touch sensitive display or connect via Wi-Fi a PAD, Smartphone or PC and OPC-UA

Not designed for:

- Viscosity higher than 10,000 centiStoke

- Very abrasive materials for a long time